How to Properly Store Your Brake Disc Replacement Tool for Longevity and Efficiency

Jan 19,2026

How to Properly Store Your Brake Disc Replacement Tool for Longevity and Efficiency

Table of Contents

Understanding the Importance of Proper Tool Storage

Choosing the Right Storage Environment

Preparation Before Storage

Best Practices for Storing Your Brake Disc Replacement Tool

Maintenance Tips for Your Brake Disc Replacement Tool

Common Mistakes to Avoid When Storing Too

How to Properly Store Your Brake Disc Replacement Tool for Longevity and Efficiency

Table of Contents

- Understanding the Importance of Proper Tool Storage

- Choosing the Right Storage Environment

- Preparation Before Storage

- Best Practices for Storing Your Brake Disc Replacement Tool

- Maintenance Tips for Your Brake Disc Replacement Tool

- Common Mistakes to Avoid When Storing Tools

- FAQs About Storing Brake Disc Replacement Tools

- Conclusion

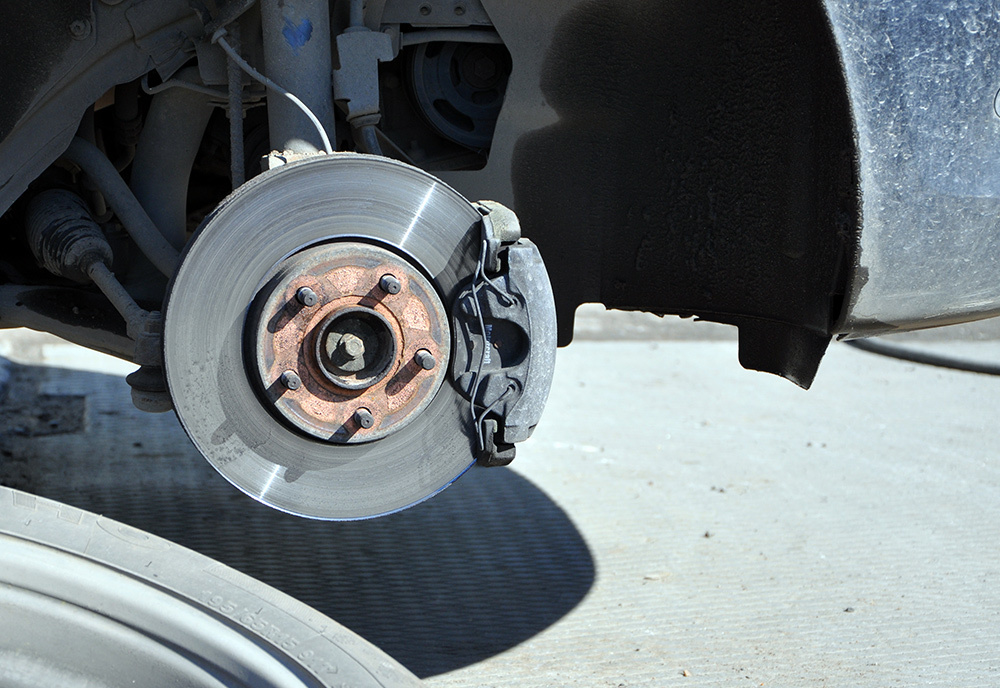

Understanding the Importance of Proper Tool Storage

Storing your brake disc replacement tool correctly is essential for maintaining its performance and extending its lifespan. Proper storage prevents rust, wear, and tear, ensuring that your tool is ready for use when you need it. The brake disc replacement tool is a precision instrument, and neglecting its storage can lead to costly repairs or replacements. By following best practices, you can ensure that your tool remains in optimal condition.

Choosing the Right Storage Environment

To maintain the integrity of your brake disc replacement tool, it’s critical to choose the right storage environment:

Temperature Control

A stable temperature is vital for tool preservation. Avoid areas with extreme heat or cold, as these conditions can affect the material properties of the tool. Ideally, store your tool in a climate-controlled space where the temperature remains consistent.

Humidity Levels

High humidity can lead to rust and corrosion. Store your brake disc replacement tool in a dry environment. Consider using silica gel packets or dehumidifiers in your storage area to absorb excess moisture.

Protection from Contaminants

Dust, dirt, and other contaminants can damage your brake disc replacement tool. Ensure the storage area is clean and free from debris. If possible, use a storage case or toolbox with a lid to keep your tool protected from environmental elements.

Preparation Before Storage

Preparing your brake disc replacement tool before storage can significantly enhance its longevity:

Clean Your Tool Thoroughly

Before storing your tool, clean it to remove any dirt or grease. Use a soft cloth and mild detergent to wipe down the surface. Avoid using abrasive materials that could scratch the surface.

Inspect for Damage

Before storage, inspect your tool for any signs of wear or damage. Look for cracks, rust, or any other issues that could affect performance. Address any problems immediately to avoid further damage.

Lubricate Moving Parts

If your brake disc replacement tool has any moving parts, apply a light lubricant to ensure smooth operation. This step prevents rust formation and ensures that the tool functions correctly when you need it.

Best Practices for Storing Your Brake Disc Replacement Tool

Implementing best storage practices can safeguard your tool from damage:

Use Proper Tool Holders

Utilize tool holders or organizers designed for automotive tools. These holders keep your brake disc replacement tool secure and prevent it from rolling around or being knocked over.

Store in an Upright Position

Whenever possible, store your brake disc replacement tool in an upright position. This minimizes stress on the tool and prevents warping or bending over time.

Label Storage Areas

If you have multiple tools, label the storage areas to make it easy to find your brake disc replacement tool when needed. This practice also encourages a tidy workspace, which reduces the risk of tool damage.

Maintenance Tips for Your Brake Disc Replacement Tool

Regular maintenance is crucial to ensure your brake disc replacement tool remains in excellent working order:

Routine Inspections

Conduct regular inspections of your tool even when it’s in storage. Look for signs of rust, wear, or other issues. Address problems promptly to avoid more significant repairs later.

Periodic Cleaning

Even in storage, tools can accumulate dust. Schedule periodic cleanings to keep your brake disc replacement tool in pristine condition. This will help maintain its effectiveness and appearance.

Keep a Maintenance Log

Maintain a log of all inspections, cleanings, and repairs. This record helps you track the tool’s condition and identifies when it might need replacement.

Common Mistakes to Avoid When Storing Tools

Being aware of common storage mistakes can help you avoid damaging your brake disc replacement tool:

Ignoring Environmental Factors

Neglecting to consider temperature and humidity can lead to rust and breakdown of materials. Always be conscious of the environment where you store your tools.

Failure to Clean Before Storage

Not cleaning your tool before storing it can lead to corrosion and permanent damage. Always take the time to clean and inspect your tools.

Improper Use of Storage Containers

Using containers that are too small or poorly ventilated can lead to damage. Choose appropriate storage that allows for airflow and protects your tool.

FAQs About Storing Brake Disc Replacement Tools

1. How often should I inspect my brake disc replacement tool?

We recommend inspecting your tool at least every few months, even if it’s in storage. This helps catch any issues early.

2. Can I store my brake disc replacement tool outdoors?

No, storing your tool outdoors exposes it to the elements. Always keep your tool in a climate-controlled, dry environment.

3. What type of lubricant should I use on my tool?

Use a light machine oil or a lubricant specifically designed for automotive tools. Avoid heavy greases that can attract dirt.

4. Is it necessary to use tool holders?

While not mandatory, using tool holders provides better protection and organization, which can prolong the life of your tool.

5. What should I do if I notice rust on my tool?

If you find rust, clean it off immediately using a rust remover or a fine abrasive pad. After cleaning, reapply lubricant to protect the surface.

Conclusion

Properly storing your brake disc replacement tool is crucial for maintaining its performance and lifespan. By following the guidelines outlined in this article—such as choosing the right storage environment, preparing your tool before storage, and performing regular maintenance—you can ensure that your tool remains effective and ready for use whenever needed. Investing time in proper storage practices not only saves you money on repairs but also enhances your overall efficiency in automotive tasks. Store wisely, maintain regularly, and enjoy the longevity of your brake disc replacement tool!

Contact

E-mail:

Phone

Add:

West of Dongwang Village, Gucheng Town, Longyao County, Xingtai City, Hebei Province