Understanding Brake Drum Failures in Agricultural Trailers: Causes and Solutions

Dec 08,2025

Understanding Brake Drum Failures in Agricultural Trailers: Causes and Solutions

Table of Contents

Introduction to Brake Drum Systems in Agricultural Trailers

The Importance of Brake Drum Maintenance

Common Brake Drum Failures in Agricultural Trailers

Causes of Brake Drum Failures

Excessive Wear and Tear

Heat Damage and Overheating

Envi

Understanding Brake Drum Failures in Agricultural Trailers: Causes and Solutions

Table of Contents

- Introduction to Brake Drum Systems in Agricultural Trailers

- The Importance of Brake Drum Maintenance

- Common Brake Drum Failures in Agricultural Trailers

- Causes of Brake Drum Failures

- Identifying Symptoms of Brake Drum Failures

- Effective Solutions to Prevent Brake Drum Failures

- Regular Maintenance Practices

- Using Quality Replacement Parts

- Importance of Professional Inspections

- Case Studies: Real-World Examples of Brake Drum Failures

- Conclusion

- Frequently Asked Questions (FAQs)

Introduction to Brake Drum Systems in Agricultural Trailers

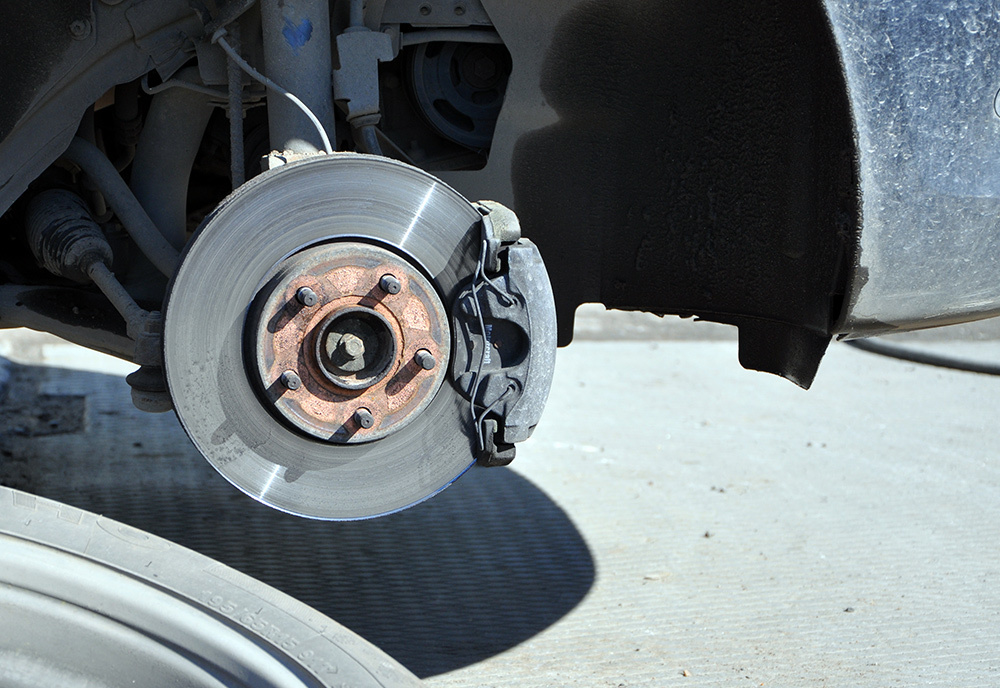

Brake drum systems play a pivotal role in the safety and performance of agricultural trailers. These components are essential for slowing down and stopping the vehicle effectively, especially when transporting heavy loads across various terrains. Understanding how brake drums function and the implications of their failure is crucial for any agricultural operation.

Agricultural trailers are often subjected to rigorous work conditions, which can accelerate wear and tear on their braking systems. By recognizing the importance of brake drum maintenance and the common issues that can arise, we can take proactive measures to avoid serious incidents and costly repairs.

The Importance of Brake Drum Maintenance

Regular maintenance of brake drums is not just a recommendation; it is a necessity for ensuring the safe operation of agricultural trailers. Neglecting brake drum care can lead to significant risks, including reduced braking efficiency, increased stopping distances, and potential accidents.

By maintaining these systems, we not only enhance the lifespan of the components but also ensure the safety of operators and animals in the vicinity. Understanding the importance of these practices can significantly reduce the likelihood of brake drum failures, making it a focal point in agricultural machinery management.

Common Brake Drum Failures in Agricultural Trailers

Brake drum failures can manifest in various forms, each presenting its unique challenges. Common types of failures include:

Excessive Wear and Tear

Excessive wear on brake drums typically arises from prolonged use without proper maintenance. If the brake linings are worn out, it can lead to metal-to-metal contact, severely damaging the drum. Inspecting the brake linings regularly can help identify this issue before it becomes critical.

Heat Damage and Overheating

Heat buildup due to prolonged braking can cause the brake drums to warp or crack. This damage can compromise braking efficiency and lead to potentially hazardous situations. Recognizing the signs of overheating is crucial to addressing this issue before complete failure occurs.

Environmental Factors

Agricultural trailers often operate in challenging conditions, including exposure to dirt, mud, and moisture. These environmental factors can accelerate wear and corrosion of brake components. Understanding how these elements affect brake drums can inform better maintenance practices to combat their negative effects.

Installation Issues

Improper installation of brake drums can lead to misalignment and uneven wear, significantly increasing the risk of failure. Ensuring that all components are correctly aligned and installed will help maintain the integrity of the braking system.

Identifying Symptoms of Brake Drum Failures

Recognizing the symptoms of brake drum failures is essential for timely intervention. Common indicators include:

- **Unusual Noises:** Grinding, squeaking, or banging sounds when braking may indicate wear or damage.

- **Vibrations:** If the trailer shakes during braking, it could point toward warped brake drums or uneven wear.

- **Decreased Braking Performance:** Noticeable increases in stopping distances or the need for more force on the brake pedal can signal issues.

- **Visual Damage:** Cracks, scoring, or discoloration on the brake drum surface are clear indicators of potential failure.

By being vigilant about these symptoms, operators can take corrective action before a failure leads to an accident.

Effective Solutions to Prevent Brake Drum Failures

To mitigate the risk of brake drum failures, implementing effective solutions is essential. Here are some approaches:

Regular Maintenance Practices

Establishing a routine maintenance schedule for agricultural trailers can help in early detection and prevention of brake drum failures. Regular inspections should include checks for wear, proper lubrication, and brake adjustment.

Using Quality Replacement Parts

When replacing brake components, using high-quality parts is crucial. Inferior components may lead to premature failure and compromise safety. Investing in reputable brands ensures reliability and longevity.

Importance of Professional Inspections

Engaging a qualified technician for routine inspections can provide an expert assessment of the brake system. Professionals can identify issues that may go unnoticed during regular maintenance, ensuring that all aspects of the braking system are functional.

Case Studies: Real-World Examples of Brake Drum Failures

Real-life examples of brake drum failures serve as critical learning opportunities. In one case, a farmer experienced brake failure during a crucial harvest season, leading to loss of crops and equipment damage. The investigation revealed that improper maintenance and lack of inspections contributed to the issue.

In another scenario, a fleet of agricultural trailers was involved in an accident due to overheating brake drums. The subsequent analysis pointed to insufficient cooling mechanisms and failure to address early warning signs. These case studies highlight the importance of proactive maintenance and timely interventions.

Conclusion

Understanding brake drum failures in agricultural trailers is essential for ensuring the safety and efficiency of agricultural operations. By recognizing the common causes and symptoms of failures, we can implement effective solutions to prevent these issues.

Regular maintenance, professional inspections, and the use of quality parts are crucial steps toward safeguarding both personnel and equipment. With the right knowledge and practices in place, we can enhance the longevity of brake drum systems and maintain optimal performance in the demanding environment of agricultural work.

Frequently Asked Questions (FAQs)

1. What are the signs that my brake drums need to be replaced?

Signs include unusual noises, vibrations during braking, decreased braking efficiency, and visible damage to the brake drum.

2. How often should I perform maintenance on my agricultural trailer's brakes?

Regular maintenance is recommended at least every six months or more frequently depending on usage and work conditions.

3. Can I replace brake drum components myself?

While some individuals may have the skills, it is best to have brake components replaced by qualified professionals to ensure safety and proper installation.

4. What types of brake drums are best for agricultural trailers?

High-quality, heat-resistant brake drums designed for heavy-duty use are recommended for agricultural trailers to withstand demanding conditions.

5. How do environmental factors impact brake drum performance?

Moisture, dirt, and extreme temperatures can accelerate wear and corrosion of brake components, leading to potential failures if not properly managed.

This comprehensive guide provides a detailed understanding of brake drum failures in agricultural trailers, helping operators take informed actions to ensure safety and performance.

Contact

E-mail:

Phone

Add:

West of Dongwang Village, Gucheng Town, Longyao County, Xingtai City, Hebei Province